italianoit

italianoit

italianoit

italianoitScenari applicativi delle guarnizioni idrauliche

(I) Applicazione nel cilindro idraulico

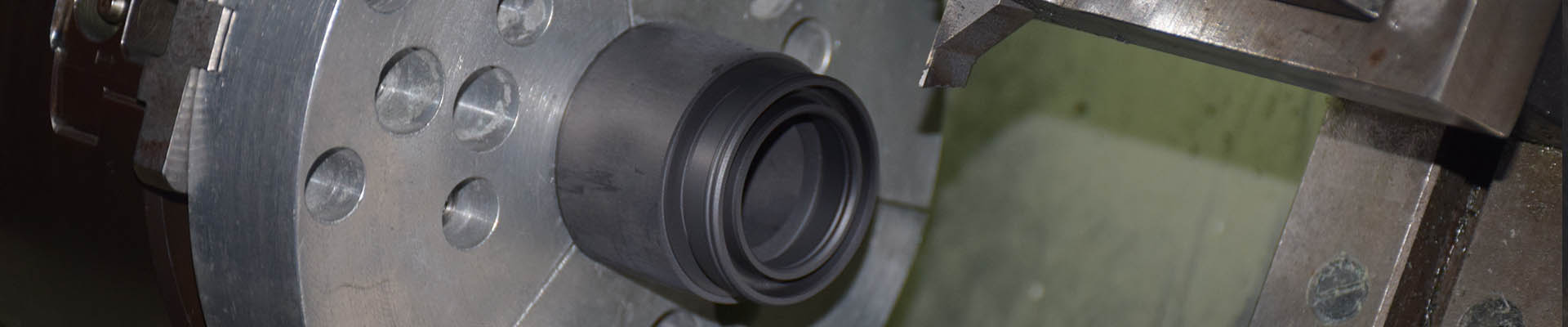

1. Guarnizione del pistone : La guarnizione del pistone, situata sulla testa del pistone, è solitamente realizzata in gomma o plastica. La sua funzione principale è quella di impedire la fuoriuscita di olio idraulico dalla testa del pistone. Durante il funzionamento del cilindro idraulico, la guarnizione del pistone può mantenere buone prestazioni di tenuta a diverse pressioni di esercizio grazie alle caratteristiche del suo materiale, garantendo il normale funzionamento del sistema idraulico.

2. Guarnizione dell'asta : La guarnizione dello stelo si trova sullo stelo del pistone ed è generalmente realizzata in materiali come gomma o poliuretano per resistere ad alte pressioni e alte temperature. Può prevenire efficacemente la fuoriuscita di olio idraulico dallo stelo e garantire la stabilità del funzionamento del cilindro idraulico. In alcuni ambienti di lavoro ad alta pressione e alta temperatura, le prestazioni della guarnizione dello stelo sono particolarmente importanti. Le sue buone prestazioni di tenuta possono garantire il normale movimento dello stelo del pistone e impedire che eventuali perdite di olio idraulico contaminino l'ambiente circostante.

3. Guarnizione del cilindro : La guarnizione del cilindro si trova sul corpo del cilindro idraulico ed è realizzata in materiali come gomma o poliuretano per resistere ad alte pressioni e alte temperature. La funzione della guarnizione del cilindro è quella di impedire la fuoriuscita di olio idraulico dal corpo del cilindro e garantire la tenuta complessiva del cilindro idraulico. Nei macchinari e nelle attrezzature pesanti, come escavatori e fresatrici, l'affidabilità e la durata della guarnizione del cilindro sono fondamentali. Un guasto della guarnizione può causare il malfunzionamento della macchina e persino causare danni e lesioni personali.

(II) Applicazione in altri macchinari

1. Per la sigillatura di giunti di tubi, coperture terminali di componenti e altri elementi di fissaggio, si utilizzano comunemente tamponi di carta, tamponi di rame, tamponi di alluminio o sigillanti. Questi materiali sigillanti svolgono un ruolo importante nella sigillatura degli elementi di fissaggio e possono prevenire efficacemente la perdita di olio idraulico. Diversi materiali sigillanti sono adatti a diversi ambienti di lavoro e requisiti. Ad esempio, in alcuni ambienti ad alta temperatura e alta pressione, potrebbero essere necessari materiali sigillanti resistenti ad alta temperatura e alta pressione.

2. Le tenute tra parti mobili, come gli O-ring, sono ampiamente utilizzate; gli anelli a V vengono utilizzati per sigillare cilindri idraulici e steli di pistoni a bassa velocità relativa, mentre gli anelli a Y vengono utilizzati per sigillare cilindri idraulici ad alta velocità relativa. L'O-ring ha una sezione trasversale a forma di O, una forma semplice ed è realizzato in gomma. Viene utilizzato principalmente per la tenuta statica nei sistemi idraulici. È ricco di varietà e adatto a vari materiali. Le dimensioni e le scanalature sono standardizzate e possono ottenere una tenuta efficace per olio, acqua, aria, gas e vari fluidi chimici. Gli anelli a V devono essere utilizzati con anelli di supporto e anelli di pressione. Offrono buone prestazioni di tenuta e il numero di anelli di tenuta può essere determinato in base alla pressione. Tuttavia, hanno una struttura complessa e un'elevata resistenza all'attrito. Sono adatti per cilindri idraulici a bassa velocità e alta pressione di esercizio. Gli anelli a Y vengono utilizzati per sigillare cilindri idraulici ad alta velocità relativa. Il rapporto larghezza-altezza della sezione trasversale è maggiore di 2, il labbro di lavoro è più corto di quello non di lavoro e viene utilizzato per fori e alberi. Non rotola durante l'uso e può soddisfare i requisiti di tenuta dei movimenti ad alta velocità.

(III) Applicazione in diversi ambienti

1. A seconda delle materie prime, diverse guarnizioni sono adatte a diversi ambienti, come la resistenza agli acidi, agli alcali, al calore, alle basse temperature, agli oli, ecc. Diversi ambienti di lavoro richiedono guarnizioni diverse. Ad esempio, in alcuni ambienti acidi sono richieste guarnizioni resistenti agli acidi; in ambienti ad alta temperatura, sono richieste guarnizioni resistenti al calore. Il materiale e le prestazioni della guarnizione determinano il suo ambiente di applicazione. Pertanto, quando si sceglie una guarnizione, è necessario scegliere una guarnizione adatta in base allo specifico ambiente di lavoro.

2. La temperatura è il fattore principale che influenza la durezza della guarnizione. Per mantenere l'elasticità della guarnizione in gomma a basse temperature, è necessario aggiungere adesivi. L'immersione prolungata nel mezzo operativo ne causerà l'invecchiamento e l'accorciamento. Le guarnizioni devono essere controllate frequentemente e sostituite tempestivamente in caso di anomalie. La temperatura ha un'influenza importante sulle prestazioni della guarnizione. In un ambiente a bassa temperatura, è necessario aggiungere adesivi per mantenere l'elasticità della guarnizione in gomma. Tuttavia, l'immersione prolungata nel mezzo operativo assorbirà gradualmente l'adesivo, con conseguente invecchiamento e accorciamento della guarnizione. Pertanto, per garantire le prestazioni e la durata della guarnizione, è necessario controllarla frequentemente e sostituirla tempestivamente in caso di anomalie. Nelle applicazioni pratiche, è possibile selezionare il materiale e la struttura della guarnizione appropriati in base ai diversi ambienti di lavoro e requisiti per migliorarne le prestazioni e la durata.

Categorie

Nuovo blog

© Diritto dautore: 2026 Guangzhou JST Seals Technology Co., Ltd. Tutti i diritti riservati.

Scansiona su WeChat