italianoit

italianoit

italianoit

italianoitWhat Are Wellhead P Seals and Why Are They Used in Casing Head Assemblies?

In oil and gas wellhead systems, sealing reliability is critical for maintaining pressure integrity and ensuring long-term well safety. Among various sealing solutions, wellhead P seals are widely used as static seals in casing heads and casing spools, especially where large tolerances and rough casing surfaces are present.

So what exactly is a wellhead P seal, and why is it commonly specified in wellhead equipment?

What Is a Wellhead P Seal?

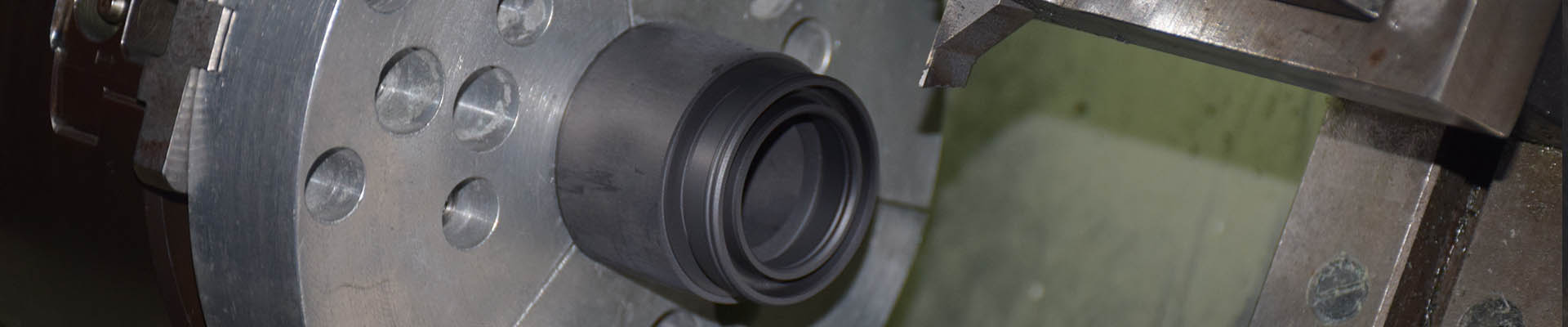

A wellhead P seal is a pressure-energized static sealing element designed specifically for use in wellhead equipment such as casing heads, casing spools, and tubing heads. It is typically installed in the lower sealing area between the casing annulus and the wellhead housing or flange connection.

Unlike conventional elastomer seals, a P seal is engineered to seal against rough or irregular casing surfaces and accommodate large dimensional tolerances commonly found in oilfield casing.

How Does a P Seal Work in Wellhead Applications?

The sealing mechanism of a P seal is based on pressure activation.

Once installed, the elastomeric sealing element is energized by injected sealant or system pressure, forcing it radially against the casing surface and the wellhead bore. To prevent extrusion under high pressure, the P seal incorporates integrated or molded-in anti-extrusion components, often supported by backup rings.

This design allows the seal to:

Maintain sealing integrity under static conditions

Compensate for casing ovality and surface roughness

Perform reliably in high-pressure wellhead environments

Where Are Wellhead P Seals Commonly Used?

Wellhead P seals are primarily used in:

Casing heads

Casing spools

Tubing heads

In these locations, they serve as a primary or secondary static seal between the casing annulus and the wellhead body or flange connection. In many wellhead designs, P seals provide redundant well safety, acting as an additional barrier to prevent pressure migration or leakage.

Why Are P Seals Preferred Over Other Wellhead Seal Types?

Compared to standard elastomer seals or simple O-ring designs, wellhead P seals offer distinct advantages:

High tolerance sealing: Effective even with large clearance gaps

Anti-extrusion capability: Reinforced by metal or wire-mesh backup structures

Static sealing reliability: Ideal for long-term wellhead service

Compatibility with rough casing: No requirement for fine surface finishes

These characteristics make P seals particularly suitable for demanding wellhead sealing conditions where conventional seals may fail.

What Materials Are Used in Wellhead P Seals?

Wellhead P seals are commonly manufactured using:

Elastomer sealing elements selected for oilfield fluids and temperature resistance

Backup materials such as wire mesh stainless steel or solid carbon steel to enhance extrusion resistance

Material selection is typically based on pressure rating, temperature range, and specific well conditions.

Wellhead P seals play a critical role in maintaining pressure integrity and well safety in oil and gas operations. Their ability to seal large tolerances, resist extrusion, and perform reliably as static seals makes them a proven solution in casing head and casing spool assemblies.

For wellhead equipment manufacturers and operators, selecting the right P seal design is essential to achieving long-term sealing performance under demanding oilfield conditions.

Categorie

Nuovo blog

© Diritto dautore: 2026 Guangzhou JST Seals Technology Co., Ltd. Tutti i diritti riservati.

Scansiona su WeChat