italianoit

italianoit

italianoit

italianoitGuarnizioni criogeniche per operazioni GNL: superare condizioni estreme con soluzioni energizzate a molla

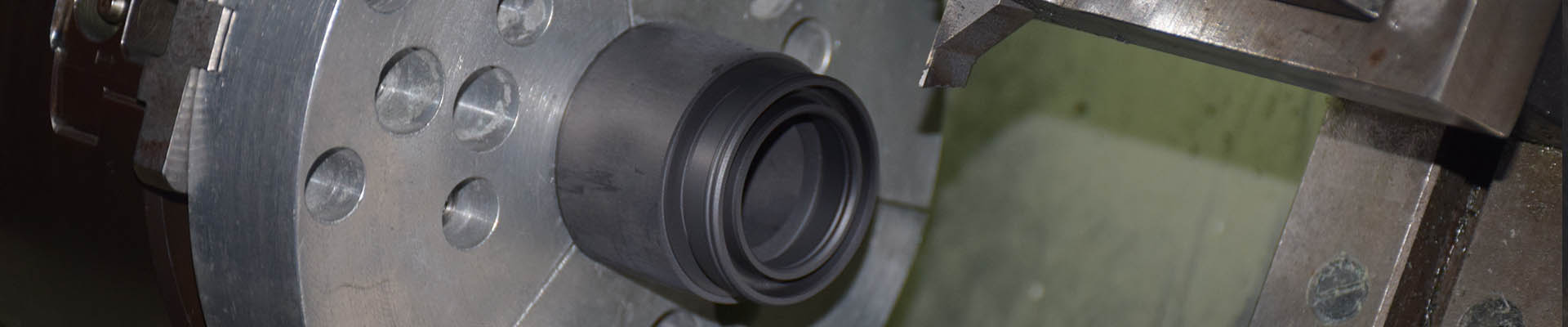

Nelle operazioni di gas naturale liquefatto (GNL), valvole e apparecchiature devono affrontare alcune delle condizioni più difficili al mondo: temperature che scendono sotto i -196 °C (-320 °F), pressioni superiori a 750 psi e cicli termici costanti che causano dilatazione, restringimento e stress dei materiali. Queste sfide richiedono guarnizioni in grado di mantenere l'integrità a lungo termine, garantendo al contempo un funzionamento sicuro e senza perdite.

Efficient, reliable valve performance is critical to the success of any LNG/CNG operation, and seals play a central role in keeping valves up and running. But their job is made difficult by the demanding service conditions.

Challenges in LNG Valve Sealing

LNG operations subject seals to unique stresses:

Spring-energized seals are vital across LNG infrastructure, including:

With the right material formulation and design, they can actually provide much better sealing service than alternative technologies, such as metallic seals, elastomeric seals and packings—especially in dynamic applications. In fact, the right polymer seals can actually help engineers achieve new levels of valve performance.

Sealing at cryogenic temperatures has its own unique set of challenges. JST has a wide range of solutions for cryogenic sealing applications. Cryogenic seals require skillful design by combining the right type of material, seal configuration, and spring energizer to overcome the dimensional fluctuation of all mating parts.

Upgrade your LNG systems with JST’s cryogenic sealing solutions —engineered to keep your operations running smoothly, safely, and leak-free.

Categorie

Nuovo blog

© Diritto dautore: 2026 Guangzhou JST Seals Technology Co., Ltd. Tutti i diritti riservati.

Scansiona su WeChat