italianoit

italianoit

italianoit

italianoitPerché il trattamento termico è così importante nella sigillatura delle molle?

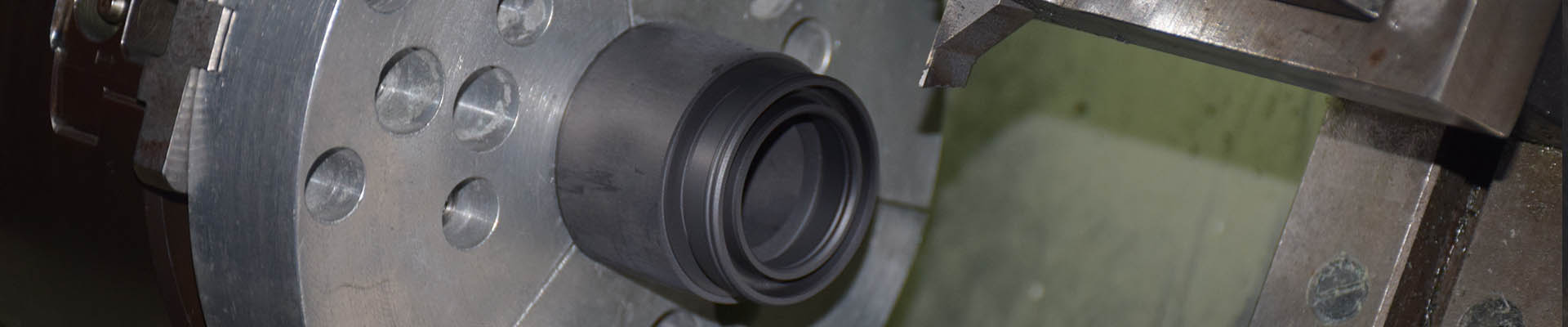

Il trattamento termico è diventato un passaggio fondamentale nella produzione di molle di tenuta , contribuendo in modo significativo a migliorarne l'efficienza, la durata e la vita utile. Questo trattamento prevede l'applicazione strategica di metodi di riscaldamento e raffreddamento, alterando intenzionalmente le proprietà fisiche e chimiche del materiale. Trova applicazione principalmente nel campo metallurgico e risulta molto utile anche in altri settori, come la produzione del vetro e i rivestimenti polimerici. L'obiettivo principale è rendere il materiale più duro o più morbido a seconda dello scopo del prodotto, ottimizzandone così le proprietà meccaniche.

Fondamentalmente, il trattamento termico garantisce un equilibrio tra il miglioramento delle prestazioni del materiale e il raggiungimento della massima economicità. Fornisce un potente meccanismo per manipolare le proprietà del metallo, regolare la diffusione e controllare i processi di raffreddamento all'interno delle microstrutture. Questo blog approfondirà il ruolo chiave del trattamento termico nella produzione di molle sigillate, fornendo un'introduzione dettagliata al processo, ai vantaggi e ai metodi comunemente utilizzati. La ricottura e altri processi di trattamento termico vengono utilizzati per alleviare le tensioni residue, rimuovere la lavorazione a freddo, dissolvere gli elementi di lega o la segregazione, ottenendo così un materiale più uniforme.

Vantaggi del trattamento termico per la tenuta delle molle

Il trattamento termico migliora notevolmente le proprietà fisiche delle molle di tenuta e ne amplia l'applicabilità in molti settori. Soddisfa esigenze industriali specifiche personalizzando le proprietà meccaniche delle molle. Il trattamento termico migliora le proprietà meccaniche della molla, ne aumenta la resistenza e la durata e ne aumenta la resistenza all'usura. Inoltre, può anche eliminare le sollecitazioni all'interno del metallo, garantendo una migliore qualità del prodotto e una migliore durata. Ciascuno di questi vantaggi è illustrato nelle sezioni seguenti.

Proprietà meccaniche migliorate

Applicando diversi metodi di riscaldamento, raffreddamento e ammollo, il trattamento termico può migliorare significativamente le proprietà meccaniche delle molle sigillate. I principali miglioramenti includono:

Maggiore resistenza e durata

Il trattamento termico può migliorare significativamente la resistenza e la durata delle molle di tenuta, migliorandone così le prestazioni complessive e la durata utile. I principali vantaggi includono:

Maggiore resistenza all'usura e alla fatica

Il trattamento termico svolge un ruolo importante nel migliorare la resistenza all'usura e alla fatica delle molle di tenuta e presenta molteplici vantaggi:

Sollievo dallo stress nei metalli

Il trattamento termico consente un'efficace riduzione delle sollecitazioni all'interno delle molle di tenuta, offrendo diversi vantaggi:

Categorie

Nuovo blog

© Diritto dautore: 2026 Guangzhou JST Seals Technology Co., Ltd. Tutti i diritti riservati.

Scansiona su WeChat